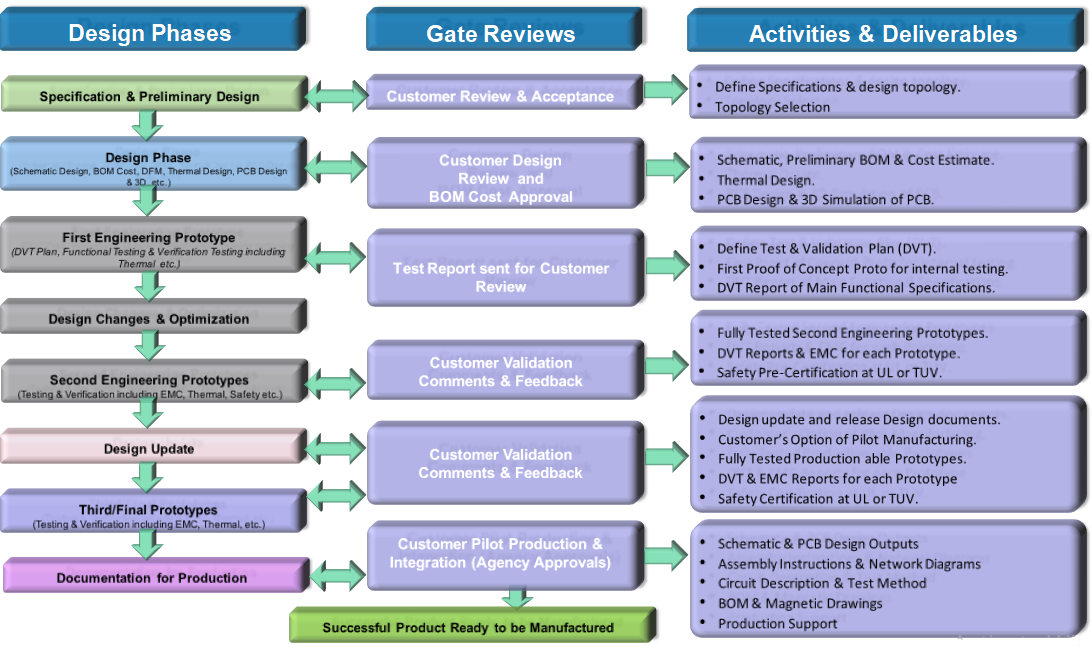

Delivery Model

Our specialist design expertise and range of services is focused to meet Customer needs worldwide. Our Global Delivery model provides for a seamless transition of technology from our laboratories to our Customers across multiple global locations. Thus we can work side-by-side with your design team or independently, to help you put together effective design strategies.

Our “Global Delivery Model” Process that helps each Project always succeed!!

A complicated design process is simplified by our vast experience in designing power conversion units from a few watts to 20 kW.

- Step 1: A detailed Test Plan of the specification describing test methods is made.

- Step 2 : Study of different topology options, design solutions and choose the most optimum one for the given requirements.

- Step 3 : Design of Schematic Diagram based on computations and simulations using soft tools and verifying results on a breadboard.

- Step 4: Thermal design.

- Step 5: Design of Magnetic Components.

- Step 6: Bill of Material with cost and sources.

- Step 7: PCB Design in accordance with DFM.

- Step 8: 3 D simulated drawings of the completely populated product.

Most of our designs reach production stage with only two cycles of prototypes!!

- Step 1: The first cycle of hand made prototypes are built and tested completely in accordance with the detailed Test Plan including EMC, Thermal, HALT, Safety etc. before sending it to customer for validation in their systems.

- Step 2 : Build cycle two after review by customer to incorporate all requirements to deliver a production ready sample. These samples too are tested completely in accordance with the detailed Test Plan including EMC, Thermal, HALT, Safety etc.

Documentation designed to suit the customer’s production process, as you would have done for a design developed in-house!!

- Blue print of the product with complete Bill of Material with three alternate sources with cost.

- Product Assembly Instructions with 3D pictorial representations of the complete assembly process.

- Schematic Diagram description with explanations and waveforms.

- Testing and Trouble shooting of production units.

- Product Maintenance Manual and User guide.